PCB size: 24*24”(max); 16*16”(min)

Board thickness: 0.05~2.0mm

FPC size: 16*16”(max); 9.8*9.8”(min)

Board thickness: 0.036~1mm

Conveyor speed: 0.2~1.6M/min(adjustable)

Plating window: 610*3000mm/tank(PCB);

400*3000mm/tank(FPC)

Current density: 35ASF(max)forDC Rectifer

Anodestyle: can be used with insoluble and soluble anode

Cathode type: Continuousvertical panel clamping type

Board space: 5mm

Characteristicsdescription:

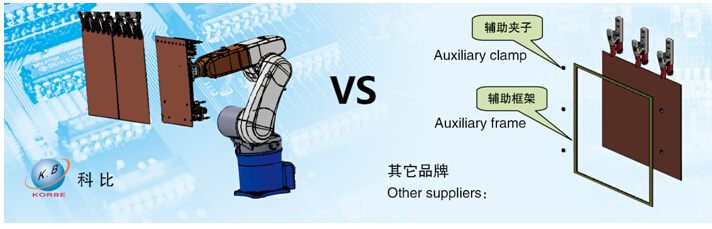

0.036 mm FPC without auxiliary frame production lines,

greatly reduced the production cost

Automatic six axis robotic armloading&unloading system,

improve the production efficiency

No transfer during loading&unloadingsystem,

reduce FPC wrinkle

FPC board cleaning without dead workingspace, no residue

Without auxiliary frame, greatly reduce thechemicals bring

in and bring out volume

No auxiliary frame use and maintenance costs

Long-term buy auxiliary frame andmaintenance costs,

increase FPC production cost

Loading and clamping auxiliary framemanually, FPC board need

transfer between different working stations,increase FPC wrinkle

It takes more operators to unloading FPC andremove the auxiliary

frame, increase labor cost

To stripping copper on auxiliary framefrequently

Auxiliary frame produce more dead workingspace, acid residue is

more difficult to clean, easy to causesurface oxidation

Auxiliary frame increase the chemicals bringin and bring out volume

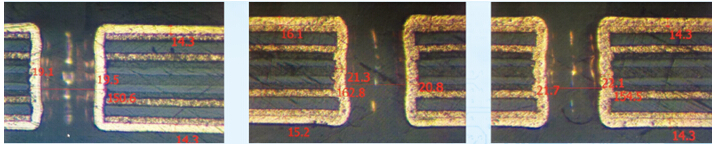

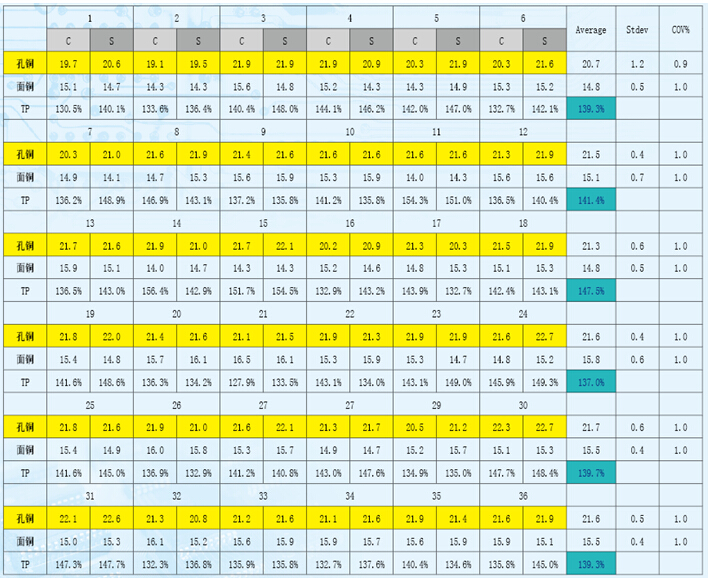

Copper platinguniformity on board surface and through hole

(FPCcustomer measured data)

process parameter:

plating time:25min current density:2.75A/dm2 copperthickness:15um